Best Practice Guidelines: Stock Management

Copyright © 2020 GoodX Software. All rights reserved.

GoodX online Learning Centre

learning.goodx.co.za

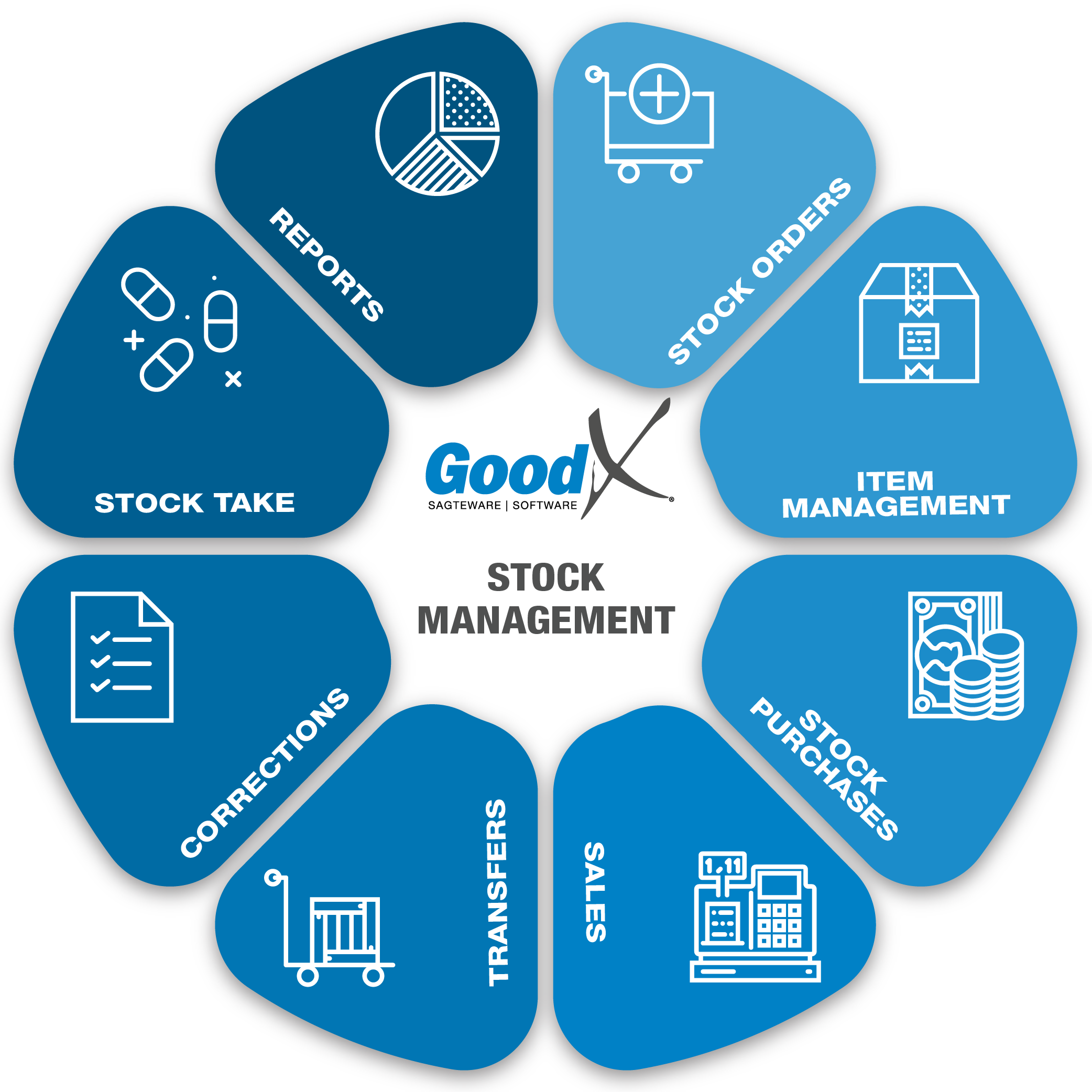

2. Understanding Stock Management

2.6. Stock Setup

First physical stock in the practice should be organised and placed in the correct locations in the practice. Next, the physical locations must be marked. After organising the stock, the system can be set up to be a mirror image of the physical stock layout in the practice.

When deciding on the setup the following should be kept in mind:

- Which information the practice wants to see

- How the information must be display

- How reports are going to be viewed

- Stock take process

Setup includes the following:

1. Categories:

Stock items are divided into categories, which categories depend on whether Medprax or IQest is used to update stock item information. When Medprax is used stock is divided into two categories namely Materials and Medicine. In the case that IQest is used there will only be one category which will include ethicals and surgicals.

2. Warehouses:

Warehouses are usually big spaces where stock items are kept. A single warehouse can be setup for the practice as a whole or multiple warehouses can be setup for example Pharmacy, Room 1, Bulk storage, etc.

Billing will be done from a service centre that is linked to a warehouse. The movement will be tracked per warehouse.

Reports can also be drawn per service centre to indicate which stock was used in each room. Multiple service centres can be linked to a single warehouse, but multiple warehouses cannot be linked to a single service centre.

3. Counting Locations:

Counting locations assist with stock takes by indicating where items are located within the warehouses. Here are some counting location examples: Shelf 1, Fridge, Glass cabinet. Counting locations only assist in the stock take process and do not track movement. They can also assist the controller in locating a specific item within the practice.

An Item can be linked to multiple counting locations. The system will add the stock together when consolidating takes place. This ensures that the person who is counting the stock does not run around trying to add all the quantities in different locations together.

4. SubClasses:

SubClasses are used to group items together. For example needles, syringes, first aid, etc. SubClasses can be used to do cycle counts and stock reports can be drawn per subclass.

Fundamental stock will only have a single warehouse setup and can have one or multiple counting locations. A practice with a fundamental setup will usually have between 200 and 300 items or less. These practices also do not want to see the specific quantity per room/consultation room.

Single Warehouse

When the practice only wants to see how much stock is in the practice and do not need to see the stock levels per room or location, a single warehouse setup will work perfectly.

Single or Multiple Counting Locations

The amount of counting locations that will be setup depends on the total amount of stock items in the practice. It is best practice to allocate no more than 20 to 30 items to one counting location, and if the same item is stored in multiple locations in the practice, there should be multiple counting locations setup.

Multi Warehouse

When the practice needs to view reports per warehouse then multiple warehouse setup will be used. The setup will normally be used for practices with more than 500 to 800 items in the practice. The multiple warehouse setup will also be used at hospitals that have theatres and a pharmacy.

The multiple warehouse setup can also be used if there is more than one stock controller and each controller is responsible for an area.

Examples of multiple warehouses will be:

- Main Warehouse

- Pharmacy

- Bulk Storeroom

- Consultation room

- Ward A/B

- Theatre storeroom

Multi Counting locations per Warehouse

Each warehouse will have its own counting locations. If the same type of locations (same name) are in different warehouses, the counting location can be linked to each warehouse. The items will not copy (if there were items in the counting location link to another warehouse) and must be linked in their own sequence.

Transfers

Remember when multiple warehouses are used, transfers will be used to stock up the other warehouses/rooms. This needs to be done on a daily basis to ensure correct stock levels per warehouses and correct stock levels per practice/hospital.

There needs to be a person responsible for all the transfers.

Sub-Classes (Cycle counts)

Subclasses are necessary to be able to do cycle counts in the GoodX system. Every item that a cycle count is done on, should be linked to a subclass.